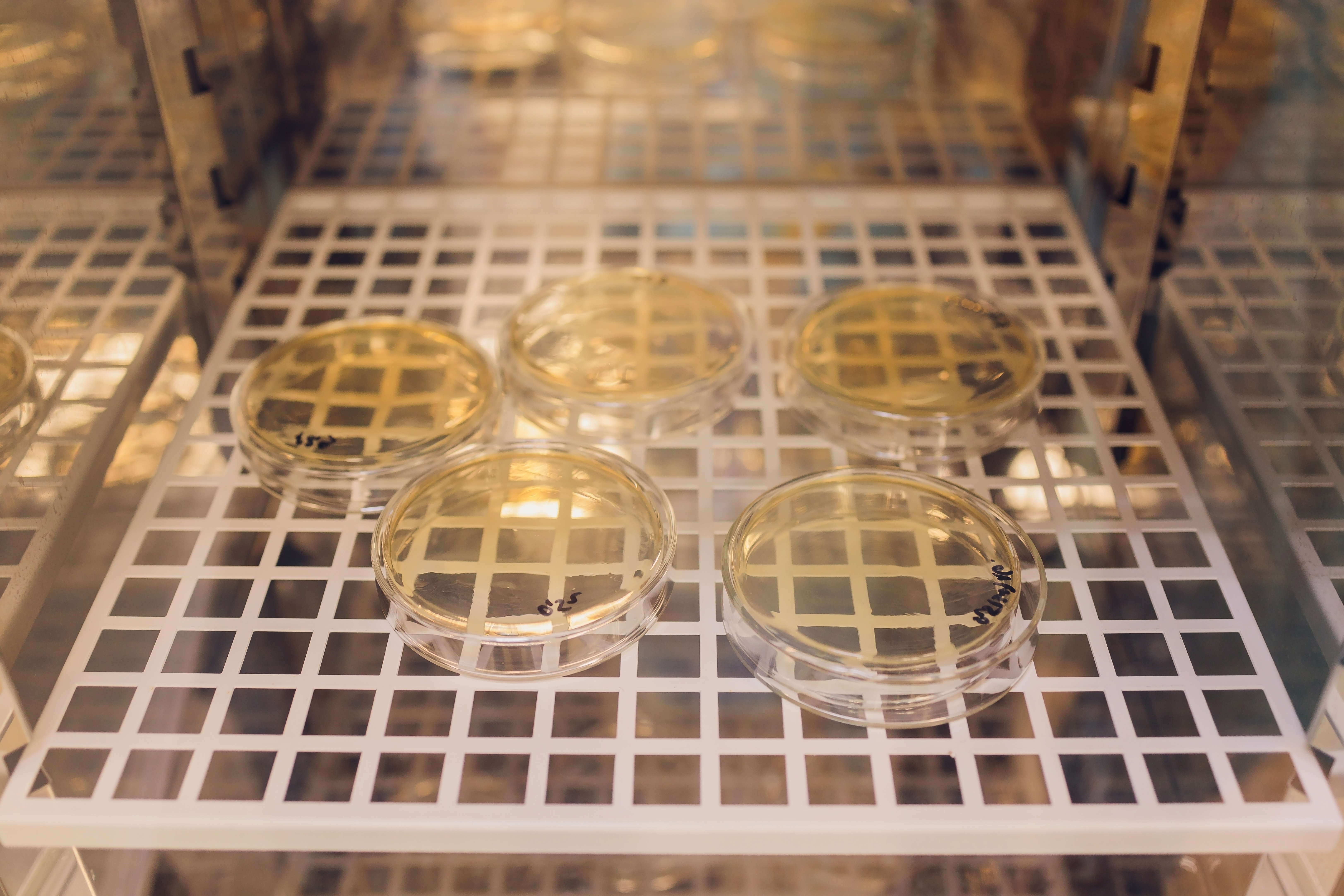

Product health and safety have always been the cornerstones of sustainable business operations at SICIT Chemitech. The quality control laboratory is the hub where the high quality of products is guaranteed through a series of meticulous tests. From the verification of incoming chemical products to checks during the production process and the analysis of finished products, the laboratory ensures compliance with strict technical specifications and the high quality standards set by regulations.

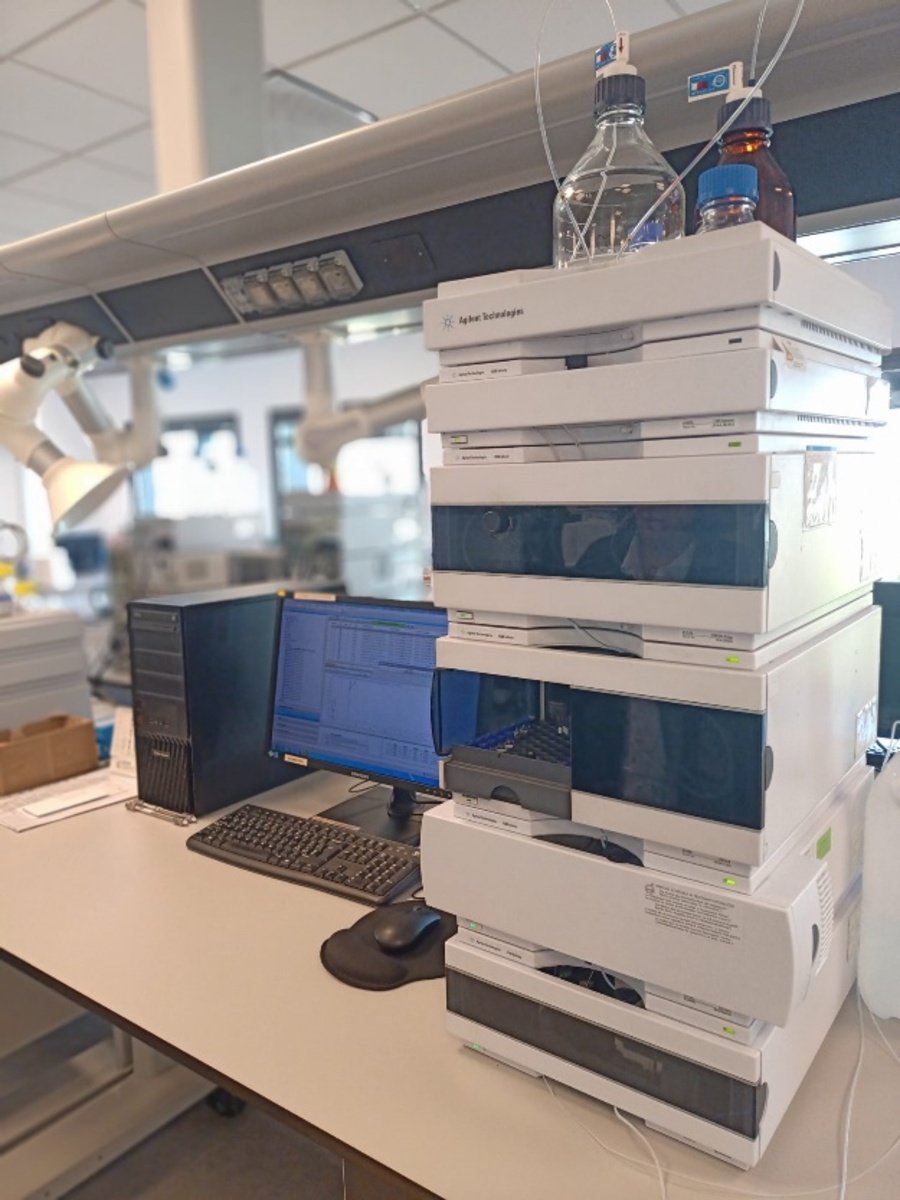

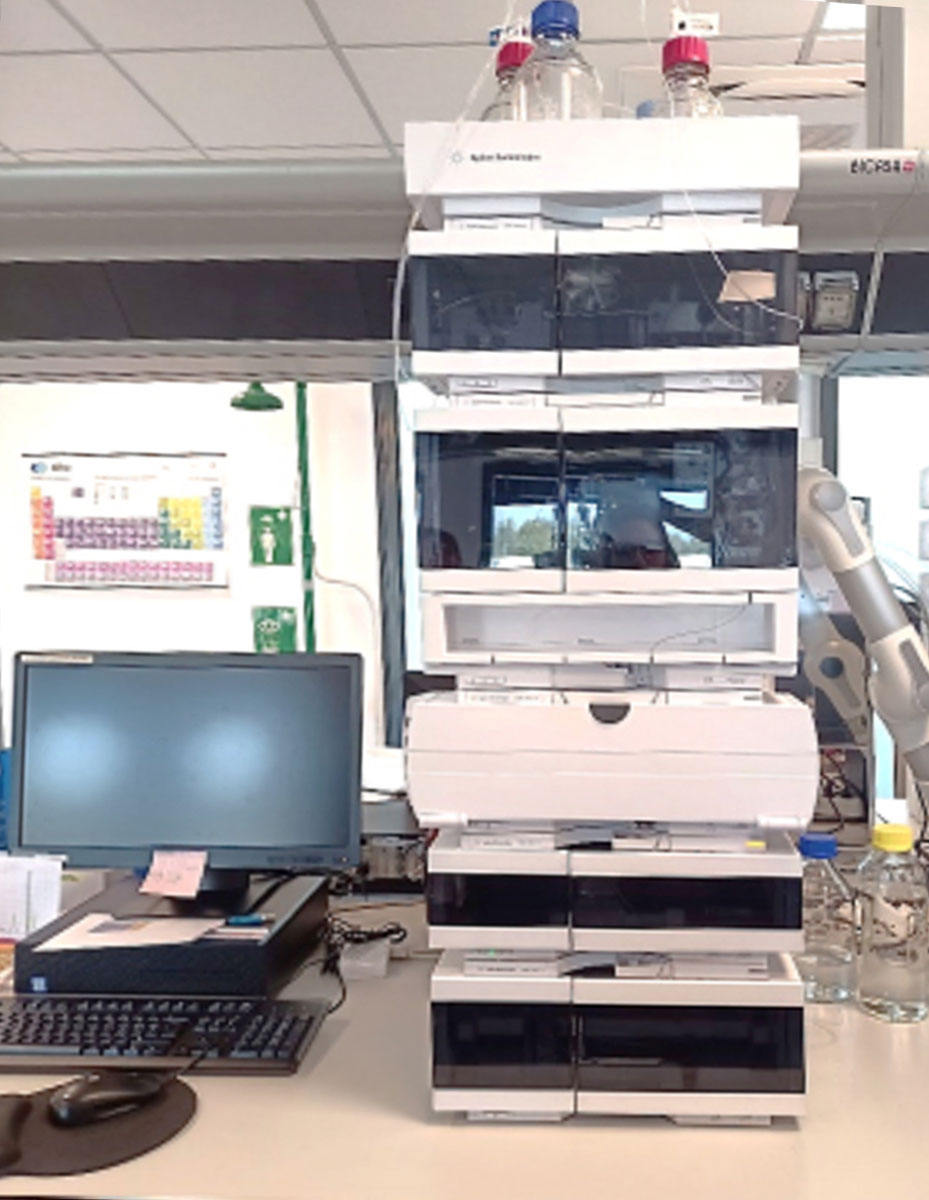

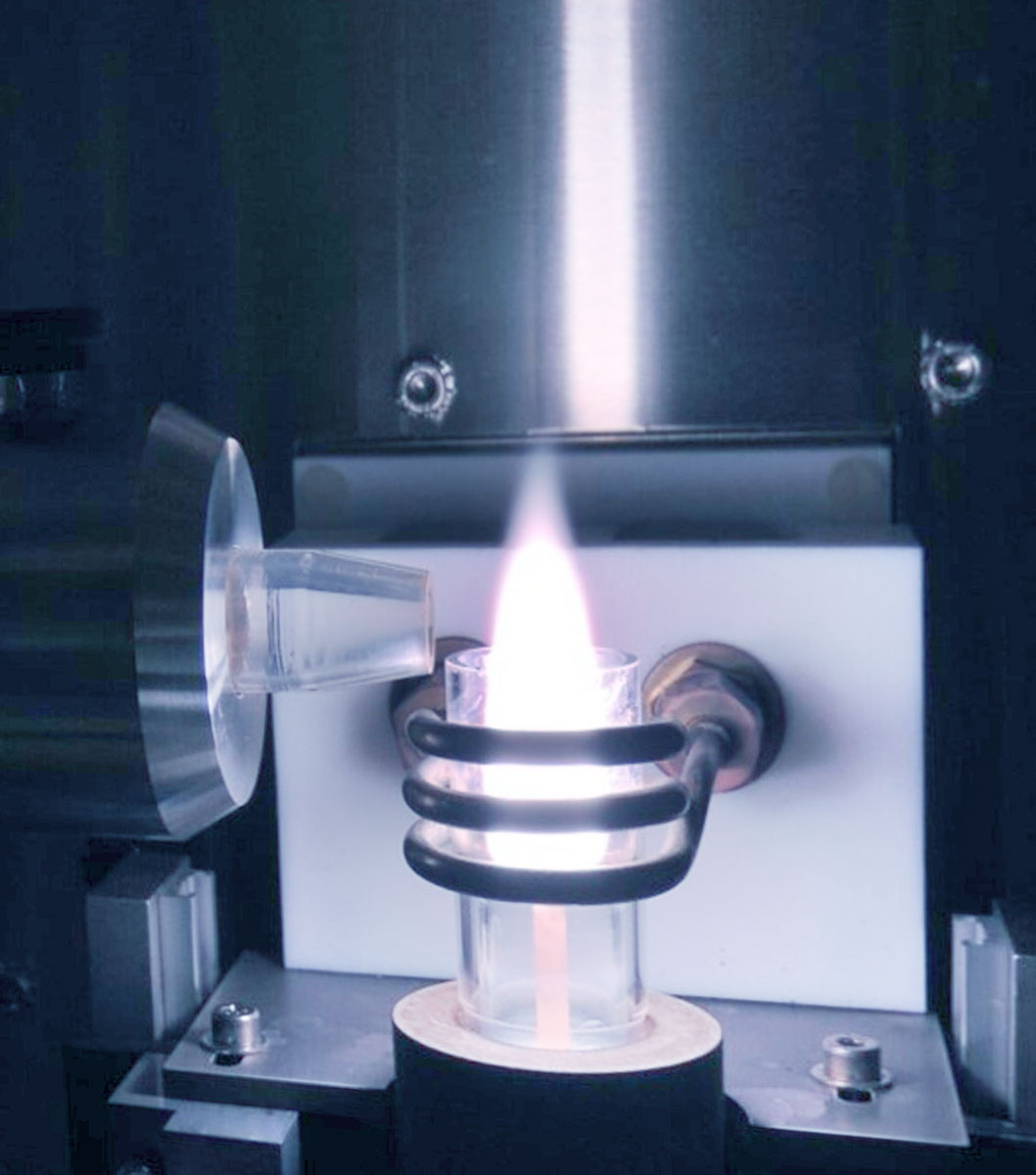

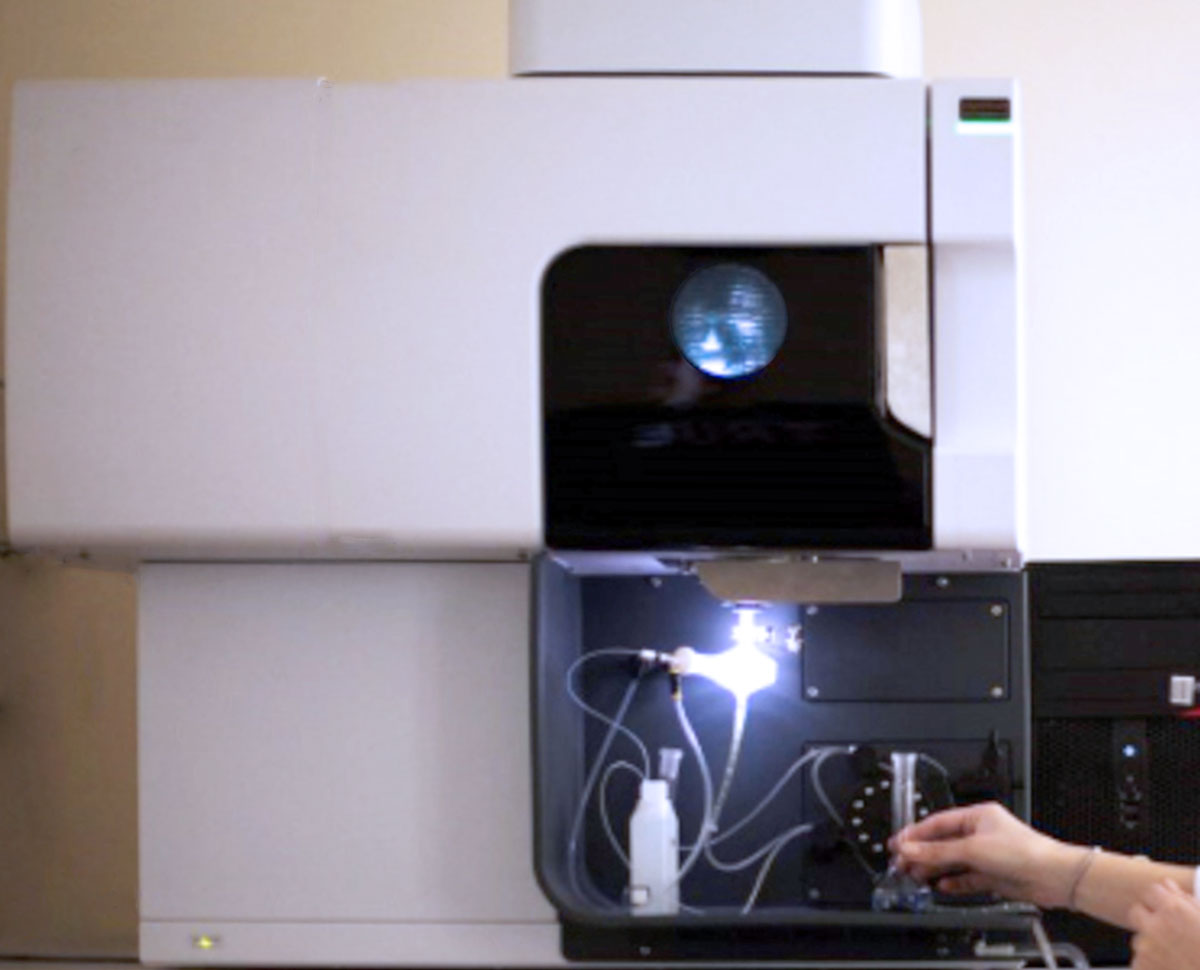

Thanks to its extensive experience and knowledge in the field of analytical determinations, especially in the characterisation of protein hydrolysates, SICIT Chemitech excels in efficiency and precision, using a UNI EN ISO 9001:20151 compliant quality management system. This excellence was further enhanced by the significant expansion and technological modernisation in 2021, which included the acquisition of advanced instruments.

A total of approximately

8.000 samples each year are managed

ensuring a comprehensive and detailed analytical coverage.

The traceability procedure adopted by SICIT Chemitech is an excellent example of its commitment to ensuring transparency and safety at every stage of the production process.

Each batch of final product is rigorously identified with a unique number, establishing a direct link with the relevant batch of raw material.

This methodology not only provides customers with in-depth knowledge of the products they purchase, it is also essential for rapid and targeted intervention in the event of non-conformities being detected. The Sales Department deals with customer reports, while the Quality Control Department intervenes in matters of analytical compliance or organoleptic problems, demonstrating an integrated and responsive company system.

The constant strive for operational excellence and effective response to customer needs result in a quality commitment that goes beyond mere regulatory compliance, attesting to the company's professionalism and responsibility towards its stakeholders.